The Status Quo

The Perfect Fit

At Precision Quincy, we champion a collaborative concepting and design approach that leads to industrial ovens with a “Perfect Fit” for both new equipment and retrofits.

During this collaboration, we solicit information on our customer’s product, its manufacturing process and required ramp-up and temperature uniformity requirements. This leads to designs that perform at or above a customer’s expectations.

But to achieve a Perfect Fit, this collaboration needs to also extend to those who operate the industrial oven. This feedback is critical to optimizing a design for maintenance, service and cleaning.

When considering whether Precision Quincy is the Perfect Fit for you, we ask that you consider the cost of the equipment for its entire life cycle: not only the cost of acquisition, but also the cost of downtime connected with cleaning, service and maintenance.

Even if your oven was not designed with maintenance in mind, there are opportunities to retrofit your existing equipment to incorporate these concepts.

Our Approach to Achieve the Perfect Fit

To achieve a Perfect Fit, we perform failure mode analysis and visualize service operations when designing new equipment.

For Example:

- If the customer’s product fails, how easily can it be removed?

- Does the process produce dust? If yes, how can it be removed?

- If the fan wheel become loose, can it easily be accessed and retightened?

Our process to ensure optimal design for cleaning, service and maintenance:

- Discussions to fully understand the customer’s process and concerns.

- Designing the optimized solution.

- Review the design and ensure access to all components.

- Submit the design to the customer for review.

- Receive feedback and incorporate the changes.

- Repeat steps as needed.

The Status Quo and Old Rules of Thumb

Our industry was established in the first half of the twentieth century, and most companies manufacturing industrial ovens today have roots that can be traced back to that era.

The engineers who founded those original companies designed equipment using the best technology and manufacturing techniques available at the time, and most of today’s companies continue to use old “rules of thumb” that are no longer applicable with the advent of modern manufacturing techniques.

Laser technology for cutting sheet metal and quick-change tooling allow manufacturers to design components of any size and shape with the precision and tolerances required for custom new equipment and retrofitted industrial ovens.

One of these old “rules of thumb” applies here: namely, that designing an industrial oven with adequate maintenance and cleaning access is cost prohibitive.

The Status Quo vs. The Perfect Fit

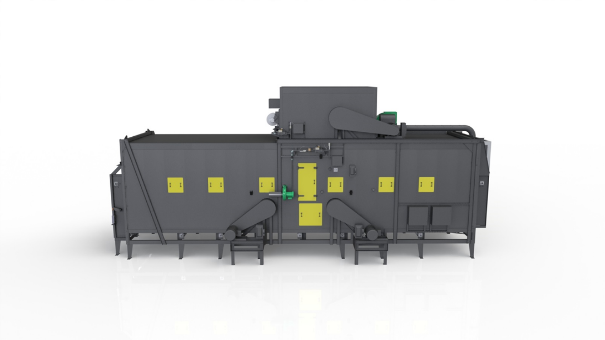

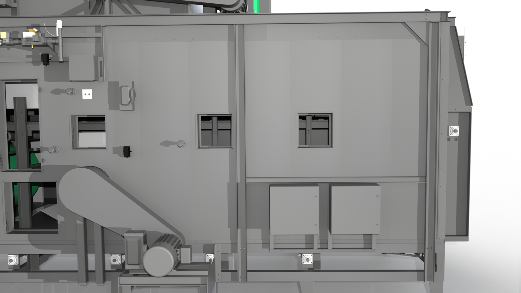

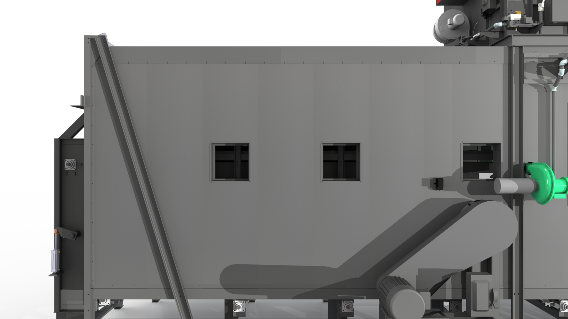

The Status Quo

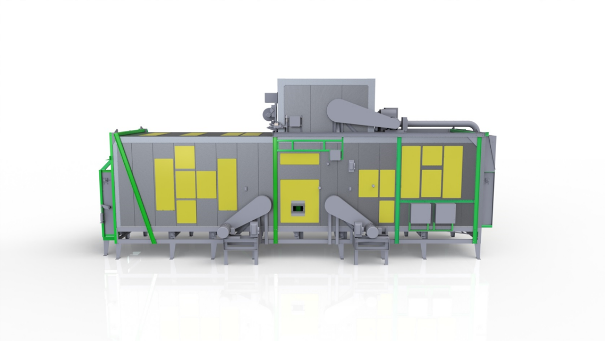

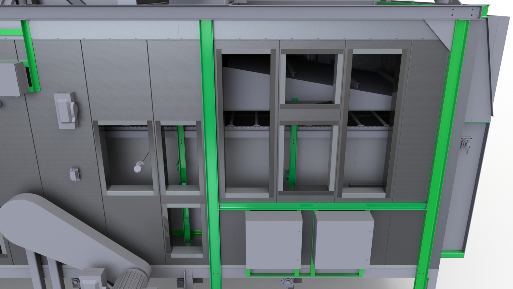

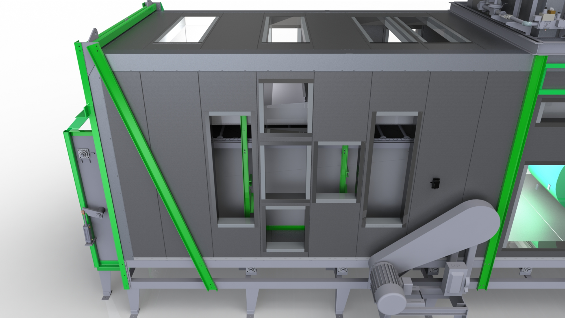

The Perfect Fit

Historically, so-called “status quo” designs incorporated only enough access to allow for proper explosion relief and inspection. Access to facilitate cleaning and service was not included because it was considered cost-prohibitive.

From the renderings above, you can see that there was only a small port every couple of feet for inspection in the Status Quo design. As a result, personnel performing cleaning and maintenance were limited to entering from the center hatch.

This limited access makes proper cleaning impossible. Unclean industrial ovens can lead to other more serious issues like unplanned downtime, product damage and fire.

To achieve the Perfect Fit, Precision Quincy takes a different approach. We collaborate with the customer to understand the process by which operations personnel clean and maintain the oven to reveal and correct access impediments.

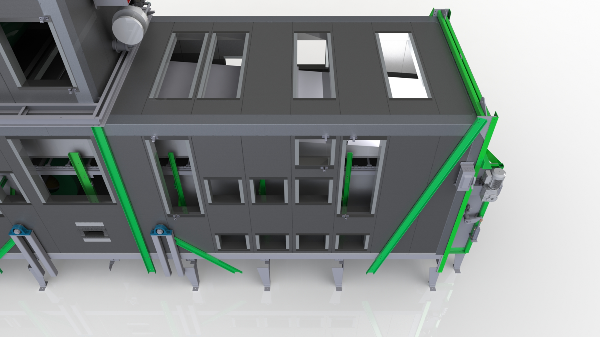

From the renderings above, you can see that once operations personnel are brought into the design process, more access for cleaning and maintenance is achieved.

Example 1

The renderings below show maintenance access for a typical Status Quo design. There is no way to access the oven floor or duct surfaces for cleaning. This results in potential product damage due to a build-up of excess coating and broken product.

At Precision Quincy, our Perfect Fit design results in better access for maintenance and reduced risk of fire. Broken product or excess coating is easily removed allowing for lower maintenance costs and shorter planned downtime periods for cleaning.

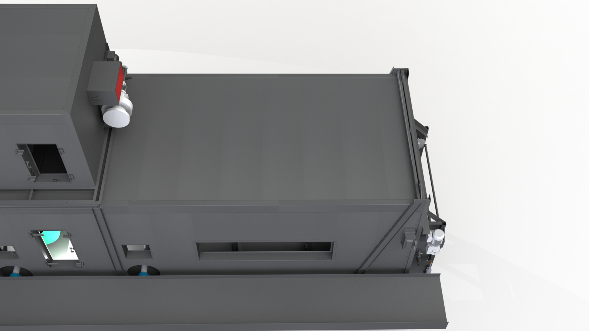

The Status Quo

The Perfect Fit

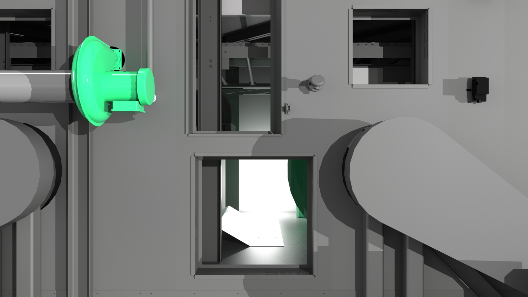

Example 2

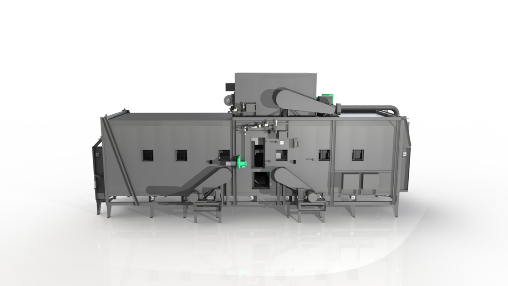

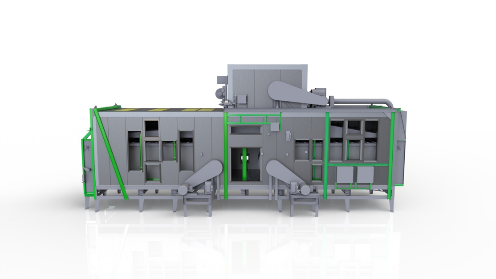

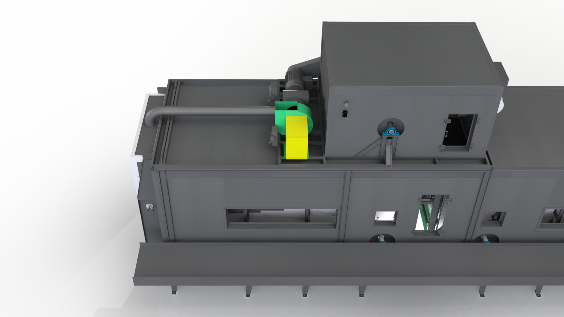

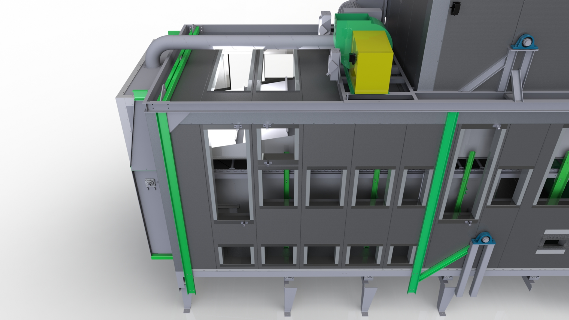

The renderings below illustrate an industrial oven’s lower zone recirculation fans. It is typical to give access but not replace the fans. At Precision Quincy, our approach revealed that operations personnel need to be able to replace the fans. In the Perfect Fit design, the entire fan wheel can be removed through the hatch without any oven modifications.

The Status Quo

The Perfect Fit

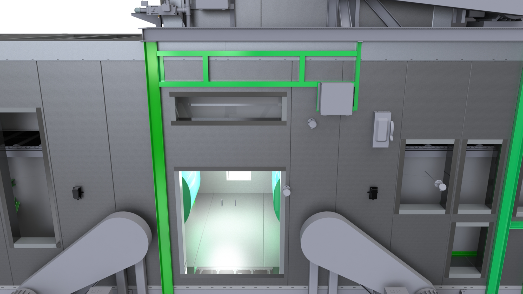

Example 3

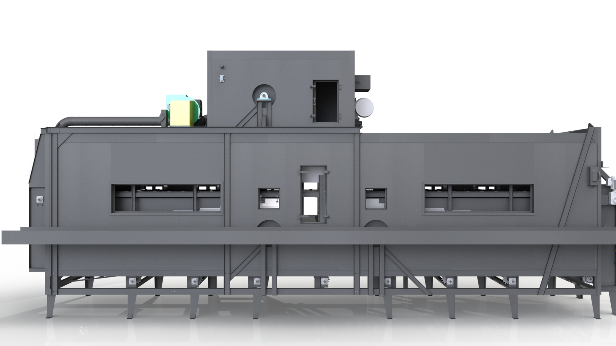

The renderings below show one side of the industrial oven. As you can see, in the Status Quo design, there is no good way to access for cleaning. In contrast, the Perfect Fit design from Precision Quincy allows access to facilitate cleaning.

The Status Quo

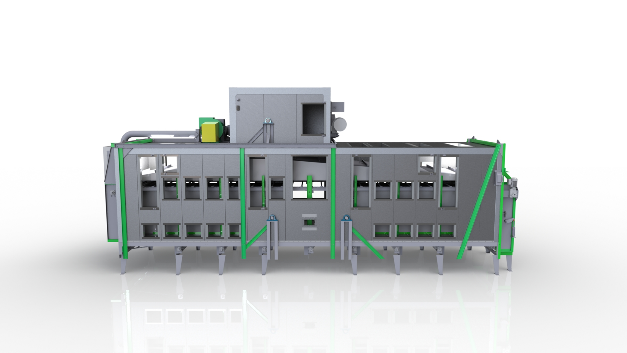

The Perfect Fit

Example 4

The renderings below show the other side of the oven. In the Status Quo design, there is better access for removing broken product, but there is no access for cleaning the areas above the ducts. In contrast, the Perfect Fit design from Precision Quincy allows access to both remove broken product and clean above the ducts.

The Status Quo

The Perfect Fit

Example 5

The renderings below give another example of the Status Quo approach where there is no access for cleaning above the ducts. In contrast, the Perfect Fit design from Precision Quincy addresses this issue.

The Status Quo

The Perfect Fit

Example 6

The renderings below are another example of the contrast between the Status Quo and Perfect Fit designs. As you can see, the Perfect Fit design from Precision Quincy results in better access for quick cleaning with less downtime.

The Status Quo

The Perfect Fit

In Conclusion

The Perfect Fit at Precision Quincy requires a collaborative approach during the concepting and design stage, and this approach must include operating personnel who are charged with maintenance responsibilities. The incremental cost of adding these design features far outweighs the additional cost from downtime caused by poor access for cleaning and maintenance.