Background

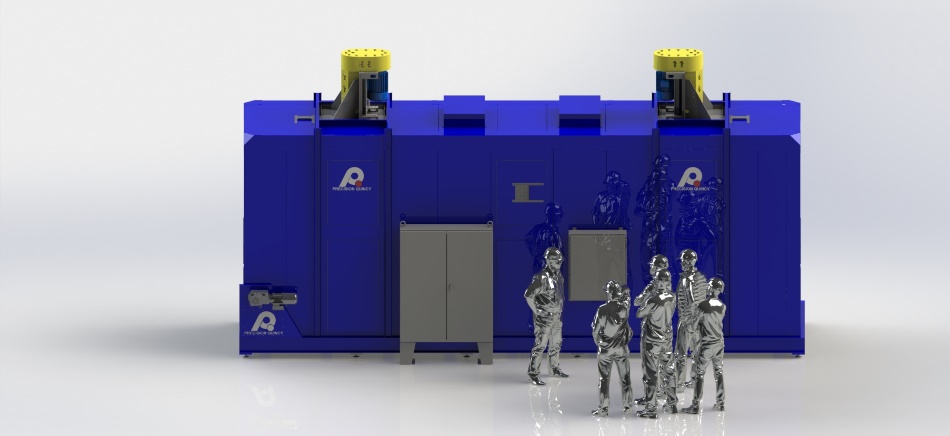

Precision Quincy designed and manufactured a preheat indexing conveyor oven used for burn-in testing of onboard charging units for an electric car manufacturer.

Industrial ovens are used to preheat electronic components to facilitate burn-in testing of electronic components. In this process, the electronic components are exposed to an elevated temperature before burn-in testing. Burn-in testing describes a process where electronic components are stressed to force early failure, known as “infant mortality.” The goal is to identify the outside conditions under which the electronic components will fail to improve the reliability of the product.

Objective: Identifying the “Perfect Fit”

Our customer needed an industrial oven to preheat onboard charging units to facilitate burn-in testing. Through our collaborative concept and design process, we solicited feedback from the customer on its overall manufacturing process and identified a need to operate in an indexing configuration. Indexing conveyors are designed to move products in a series of steps rather than a continuous flow, thus allowing time for other equipment on the line to carry out its function.

At Precision Quincy, our collaborative approach leads to a “Perfect Fit” for both new industrial ovens and retrofits.

The industrial oven system also needed to integrate with the customer’s existing programmable logic controller (PLC) system and the flow of its manufacturing process. For this indexing conveyor oven system, the onboard charging units are loaded onto pallets and indexed into the heat chamber of the oven.

Challenge: What is the Thermal Ramp-Up Rate?

The temperature setpoint for the onboard charging units was predetermined but the thermal ramp-up rate was unknown. The customer also had a tight timeframe for the project because it needed to ramp-up production to meet increased demand for its electric cars.

How Did We Achieve the Perfect Fit?

We invited the engineers from the electric car company to our facility to use our test oven. Precision Quincy is in South Beloit, Illinois — which is like other small industrial towns in the Midwest, USA.

We worked with the customer’s engineers to test the onboard charging units. The idea was to run the electronic components through our test oven to measure the different velocities at which airflow was able to heat-up the components to setpoint temperature.

Through our testing efforts, we were able to arrive at a thermal ramp-up rate and also calculate the correct indexing distance and time. The indexing system provides a signal when the oven is ready to receive a component that is conveyed through the heat chamber on a pallet. We arrived at a production rate of one pallet every two minutes with 15 stations in the oven.

We decided to use a two-strand indexing conveyor comprised of #60 RC with K1 attachments (one every pitch). One advantage of the indexing system was that all features within it could be linked to the controls and integrated with the customer’s existing PLC system.

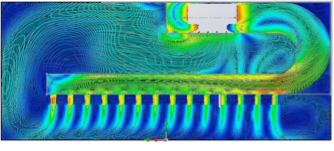

We also used computational fluid dynamic (CFD) software to improve the airflow inside the oven to maximize the output of the nozzles. For more information on Precision Quincy’s use of computational fluid dynamic (CFD) software, see Building the Better Clown Car: Computational Fluid Dynamics Leads to Better Industrial Oven Design.

Because of our testing, effective communication with the customer, and a lot of hard work from our teams, the oven was ready for delivery within the customer’s budget and timeline.

Other Features of the Conveyorized Indexing Oven

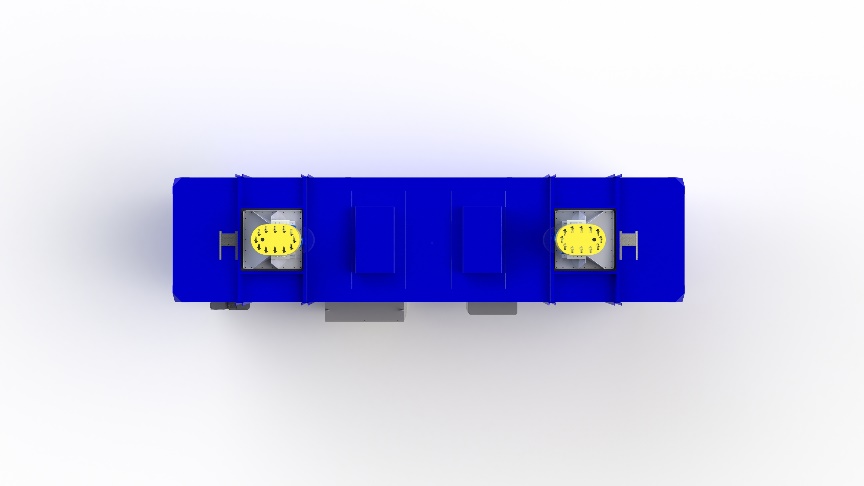

- The approximate overall dimensions of the oven: 91” (W) x 293” (L) x 155” (H) or 2,311mm (W) x 7,442mm (L) x 3,937mm (H).

- The dwell time in the heat zone was 30 minutes.

- Airflow type was vertical down, exiting on both sides.

- Airflow CFM was 21,600 ACFM @ 3.5” W.C.

- Electric heat power (144kw with Watlow DIN-A-MITE C SCR Power Control).

- Two strand indexing conveyor comprised of #60 RC with K1 attachments (one every pitch).

- UHMW slides mounted on tubes with side part guides.

- Panel rating was NEMA 12 separate high and low voltage cabinets.

- Code compliance with NFPA 86 and OSHA.

- Conveyor controls were Allen Bradley Micro 850 with 10” HMI.