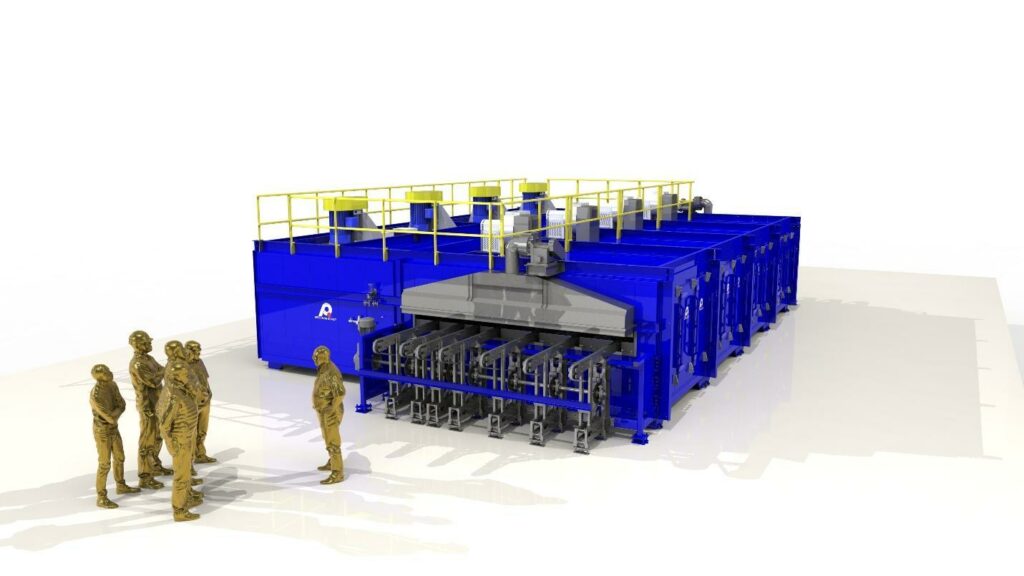

Precision Quincy delivered a cutting-edge, three-part oven system to meet the high demands of fiber cement production for a global leader in the industry.

The system includes a preheat oven, curing oven, and cooling section, designed to process up to 360,000 lbs/hr of fiber cement boards.

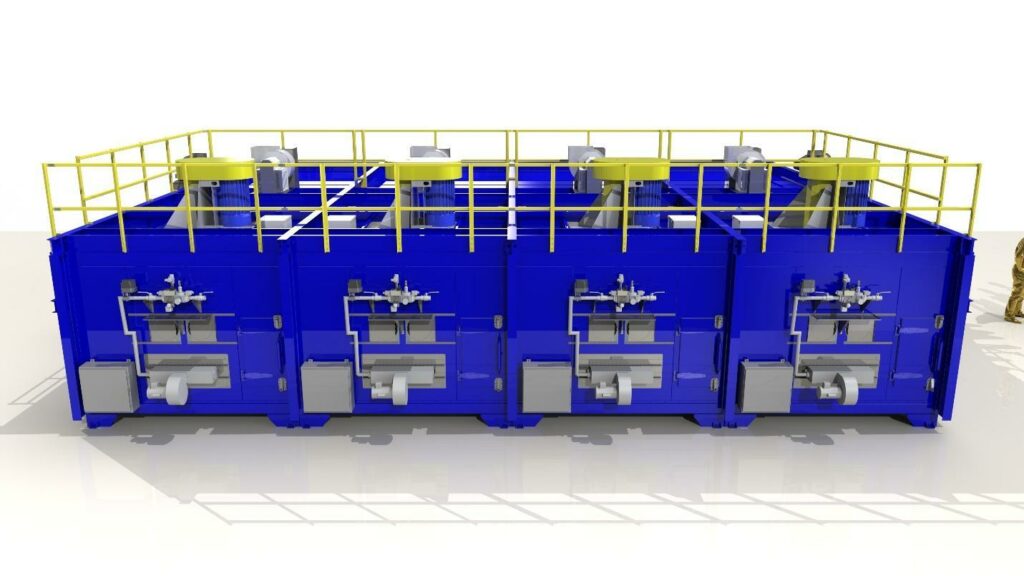

With precise temperature control, advanced airflow, and VOC safety measures, this system ensures uniform heating and cooling while adhering to NFPA 86 Class A standards.

The project showcases Precision Quincy’s ability to tailor industrial solutions for high-volume production environments, enhancing efficiency, safety, and product quality.

Precision Quincy (PQ) was commissioned by the global leader in fiber cement technology, to design, engineer, and manufacture a comprehensive industrial oven system.

The project involved a three-part system: a preheat oven, a curing oven, and a cooling section, all designed to support the high-volume production of fiber cement trim and board.

The system was built to handle large loads and high production rates, while maintaining stringent temperature control and operational safety.

The customer required a high-performance oven system capable of preheating, curing, and cooling fiber cement boards efficiently.

The system needed to process up to 360,000 lbs/hr of product, ensuring uniform temperature control while complying with NFPA 86 Class A safety standards due to the handling of volatile organic compounds (VOCs).

Curing Oven: 23.3 gal/hr.

The entire oven system adheres to NFPA 86 Class A standards, ensuring safe operation in environments where VOCs are present.

Key safety features include:

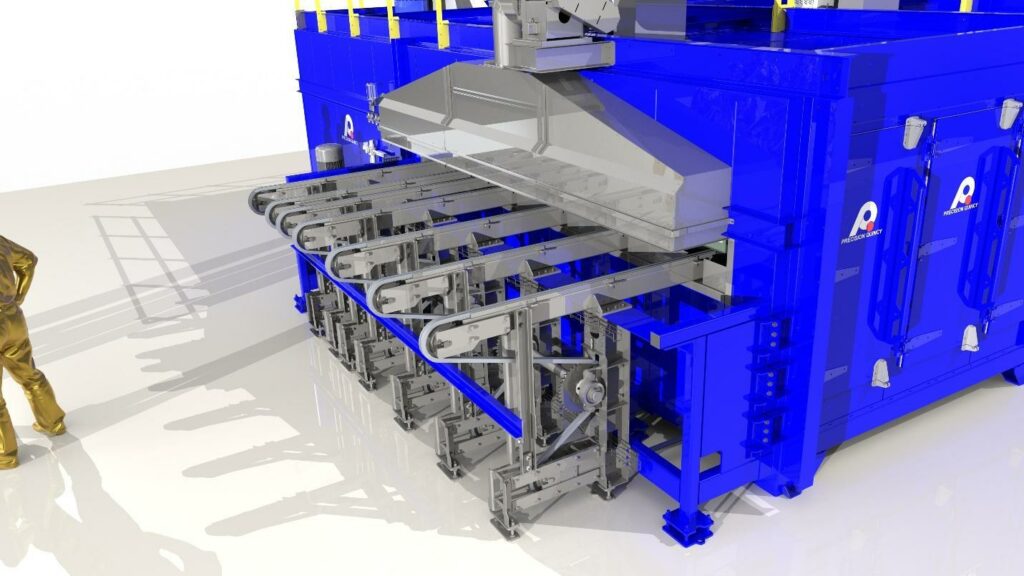

Precision Quincy conducted extensive pre-assembly and testing at their facility to ensure the oven system met the exacting standards of James Hardie:

The oven system was shipped in sections to facilitate transport and installation.

Precision Quincy provided detailed assembly prints and wiring schematics, along with on-site supervision during reassembly.

The installation process included utility connections and final calibration of the oven’s control systems.

Precision Quincy delivered a comprehensive, high-performance oven system that met the demanding production and safety requirements of the customer’s fiber cement board manufacturing process.

The preheat, curing, and cooling sections were engineered to operate seamlessly together, maximizing throughput while ensuring product quality and safety.

This project demonstrates Precision Quincy’s ability to design and manufacture customized industrial ovens that integrate advanced airflow, heating, and control systems to meet the specific needs of high-volume production environments.

Contact our experts about industrial oven repair and oven maintenance services or if you need oven replacement parts. We also do industrial oven installations!

We look forward to hearing from you, and building one of the best industrial ovens in the world for your business.

Just email us or send us a message (at right). Please allow for up to 48 business hours to receive a reply.

You can also call our industrial oven repair and parts department any time at: 815-222-9461