Precision Quincy engineered a high-performance industrial oven specifically designed for heat cleaning fiberglass rolls, delivering precision and safety at extreme temperatures.

This custom Class A oven operates at 1000°F, ensuring uniform heat distribution while handling volatile organic compounds (VOCs) generated during the process.

With advanced airflow systems, durable insulation, and a robust control interface, this oven enhances efficiency and safety for the customer.

By meeting NFPA 86 safety standards, Precision Quincy once again showcases its ability to deliver custom solutions that optimize productivity in complex industrial environments.

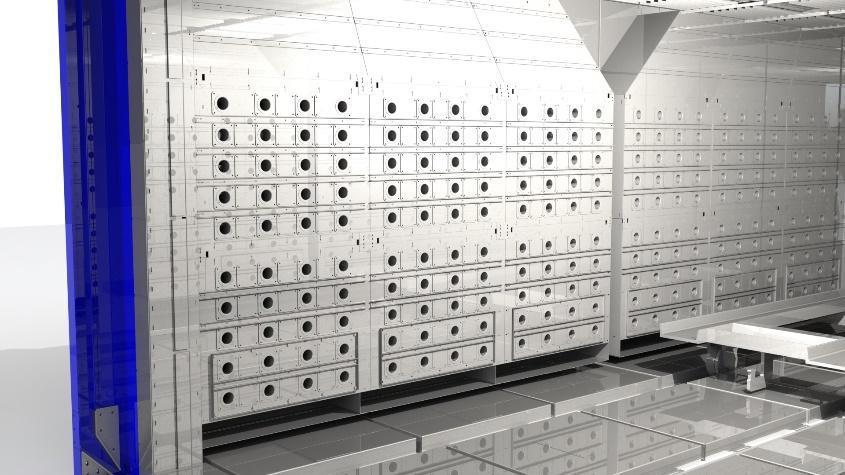

Precision Quincy (PQ) designed, engineered, and manufactured a custom industrial oven for a customer specializing in the production of fiberglass materials.

The oven was tailored to facilitate the heat cleaning of fiberglass rolls, ensuring efficient processing while complying with stringent safety standards. This high-temperature Class A oven was built to handle volatile organic compounds (VOCs) during the heat-cleaning process.

The customer required a heavy-duty industrial oven capable of handling high temperatures and large volumes of fiberglass rolls.

The oven had to provide consistent temperature control across a wide temperature range while ensuring uniform heat distribution.

Additionally, the system needed to meet NFPA 86 Class A safety standards due to the handling of VOCs, which are generated during the cleaning process.

The oven adhered to NFPA 86 Class A safety standards, specifically designed for processes involving VOCs. Multiple safety features were built into the system, including:

Precision Quincy conducted pre-assembly and pre-testing at their facility to ensure the oven met customer’s specifications. The testing phase included:

The oven was shipped to the customer’s facility, fully assembled and tested. Precision Quincy provided detailed assembly prints, wiring schematics, and operational manuals.

The customer was responsible for connecting utilities, including natural gas and electrical services, and ensuring compliance with local fire protection and safety codes.

Precision Quincy delivered a custom industrial oven designed to meet the customer’s specific requirements for heat cleaning fiberglass rolls.

The oven’s robust construction, advanced control system, and compliance with NFPA 86 Class A standards ensured safe and efficient processing of high-temperature materials.

By collaborating with the customer, Precision Quincy provided a solution that enhanced both the safety and productivity of their manufacturing operations.

This project demonstrates Precision Quincy’s expertise in delivering tailored solutions for complex industrial applications, providing high-performance ovens that meet demanding production and safety requirements.

Contact our experts about industrial oven repair and oven maintenance services or if you need oven replacement parts. We also do industrial oven installations!

We look forward to hearing from you, and building one of the best industrial ovens in the world for your business.

Just email us or send us a message (at right). Please allow for up to 48 business hours to receive a reply.

You can also call our industrial oven repair and parts department any time at: 815-222-9461